Unlike a combustion engine, you can’t feel, touch or smell an electric car battery. They are hidden from view, but they are the largest and arguably the most important component of any electric vehicle.

In this article, we’ll look at what electric vehicle (EV) batteries are made of, how they store their energy and how the technology and ownership model for batteries is developing. Fully understanding your electric car helps you get the best from it, so read on for our comprehensive guide.

What are EV batteries made of?

The majority of EVs use lithium-ion batteries, like those in consumer gadgets such as laptop computers and smartphones. Just like a phone, an electric car battery is charged up using electricity, which then is used for power, in this case to drive the car.

Whereas the batteries for most gadgets have a defined time before they are depleted, EV batteries have a ‘range’ – i.e., a distance that the car can travel before the batteries run out of charge. After this, they will need recharging again.

Electric car batteries are not a single unit, instead consisting of hundreds of cells. As a rule, a larger number of cells generally means a larger capacity battery, increasing the power available for the car’s electric motor and the total range – mileage on a charge – it can achieve.

Hybrid cars often use nickel-metal hydride batteries rather than lithium-ion. Their long lifecycles, safety and resistance to misuse make them appealing for hybrid car manufacturers. However, they have a high cost, and can lose heat or discharge themselves at high temperatures. They’re generally used in non-plug-in hybrids with much smaller battery capacities, such as the Toyota Prius and latest Honda Civic.

In comparison, lithium-ion battery technology has a high energy density and is suited to quick charging cycles – ideal for an electric car or plug-in hybrid. It also retains that energy density over thousands of such charge cycles.

How are electric car batteries made?

EV batteries are made from a combination of raw materials. ‘Base’ metals such as aluminium, copper and iron are important ingredients, but the most expensive materials are ‘precious’ metals such as cobalt, nickel and manganese, along with elements such as graphite and lithium.

These materials must be extracted or mined from the earth in a complicated and expensive way, which is why the most expensive component of an EV is its battery. Historically it’s also why an electric car was more costly to buy than the equivalent combustion cars, but as EV production ramps up this gap is reducing.

The extraction of these materials is considered by some to be controversial. Many such metals are only found in selected areas of the world, such as China and South America. Mining them can lead to issues with world politics and supply chain dominance, as well as humanitarian concerns. Lithium also uses a lot of water when being mined, causing potential problems for agriculture.1

Some manufacturers, such as Tesla and BYD are starting to use a different type of lithium-ion technology called lithium-ion phosphate (LFP). These offer many advantages including not requiring nickel or cobalt in their make-up – significantly reducing the environment and ethical impacts of producing them.

Unfortunately, similar ethical issues exist around the world with the production of petrol and diesel. Crude oil production isn’t exactly environmentally clean, while fuel prices fluctuate according to the global landscape.

In terms of local emissions, and if they are recharged from renewable energy sources, electric vehicles are generally seen as being much better for the environment.

A report from the EEA found a typical electric car in Europe produces fewer greenhouse gases and air pollutants compared with a petrol or diesel equivalent. Emissions are usually higher in the production of electric cars, but these are generally offset by lower emissions during the usage cycle.2

Volkswagen is one of several car manufacturers establishing sustainable battery production using renewable energy sources. This will become more common as increasing numbers of companies pour money and thought into environmental production processes.3

Even if the electricity used to charge an EV has been generated partially by burning fossil fuels, the increased volume and weight of these power plants allow them to be far more efficient than the internal combustion engines of petrol and diesel vehicles which are constrained by both size and weight.

How reliable are electric car batteries?

Electric (and hybrid) cars have proven to be some of the most reliable vehicles on the road. This is backed up by long warranties for EV batteries, which generally exceed the overall manufacturer warranty for the car (eight years or 100,000 miles is typical).

Just like the lithium-ion batteries in consumer electronics, EV batteries do degrade over time and through repeated charge cycles, but the drop-off in performance is far less severe than in many smaller electronic devices, such as smartphones. That’s because the number of charge cycles is far more frequent in these devices than in an EV; a much more important factor in battery degradation than age.

There are things you can do to preserve your electric car battery’s lifespan, too:

- Charge level: Maintaining a level of charge between 20-80% (unless you really need to use the full range) has been shown to improve a battery’s lifespan. Regularly discharging to the minimum and keeping it topped up to the maximum can increase the level of annual battery degradation.

- Charge speed: multiple studies suggest that minimising the amount of DC rapid charging (the fastest public chargers) improves the longevity of the battery. Using them occasionally is fine but charging via slower chargers (or a home wallbox) is best for overall health.

- Temperature: It’s not really an issue in the UK’s climate, but extreme temperatures (either cold or hot) can impact the life of an EV’s battery. Simple measures like parking in the shade can help.

How does the battery affect EV range and performance?

Rather than the amount of horsepower it has, the power output of an EV is ideally measured in kW (kilowatts). The battery’s energy storage capacity is measured in kWh (kilowatt hours) – rather like the number of litres a conventional car’s fuel tank can hold.

EV batteries are expensive and take up space, so it’s often the largest and most upmarket cars that offer the highest performance and the longest range. The smallest capacity batteries tend to be in the smallest cars.

We’ve outlined a few examples of EVs with small and large capacity batteries below.

| Manufacturer/model | Battery size | Maximum range | 0-62mph time |

|---|---|---|---|

| Volkswagen e-Up | 32.3kWh | 159 miles | 11.9 seconds |

| MINI Electric | 32.6kWh | 145 miles | 7.3 seconds |

| Honda e | 35.5kWh | 137 miles | 9.0 seconds |

| Volkswagen ID.3 | 45.0kWh | 216 miles | 8.9 seconds |

| Citroen e-C4 | 50.0kWh | 217 miles | 9.7 seconds |

| Hyundai Kona Electric | 64.0kWh | 300 miles | 7.9 seconds |

| Skoda Enyaq iV | 82kWh | 333 miles | 8.2 seconds |

| Ford Mustang Mach-E Extended Range RWD | 88kWh | 379 miles | 6.2 seconds |

| Jaguar I-PACE | 90kWh | 292 miles | 4.8 seconds |

| Audi e-tron GT 60 quattro | 93.4kWh | 303 miles | 4.1 seconds |

| Porsche Taycan Turbo | 93.4kWh | 280 miles | 3.2 seconds |

| Mercedes-Benz EQS 450+ | 108kWh | 453 miles | 6.2 seconds |

As EV battery technology evolves and gets better all the time, ranges are increasing. Mercedes-Benz has recently broken the 1,000km (621 miles) barrier with its VISION EQXX concept car.4

It’s worth pointing out that larger batteries don’t necessarily equate to longer charging times. More premium EVs tend to offer fast-charging capability that easily compensate for a bigger capacity battery.

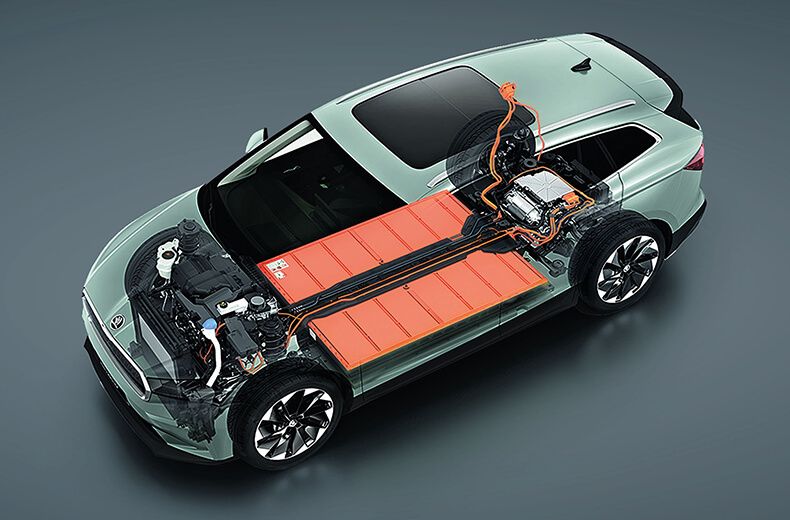

Electric car batteries are very heavy, which can affect how a car handles. However, to combat this, they are usually stored beneath the car’s floor which gives a lower centre of gravity to aid handling.

This has another benefit, too. The ‘skateboard’ chassis – so-called because when viewed from above, the chassis resembles a skateboard with the battery in the middle and the wheels at either end – liberates additional interior space. Many EVs also utilise the battery as part of the car’s structure, increasing structural strength which boosts safety and comfort.

Electric car batteries: own, lease or swap?

Unlike with some toys at Christmas, when you buy a new electric car, the batteries are included. These should last the lifetime of the vehicle. In the past, Renault, Nissan, and Smart all offered electric car battery leasing schemes, intended to reduce upfront cost and worries around EV battery degradation. However, the idea was unpopular.5

Used electric cars such as the Renault Fluence Z.E, Renault ZOE (2012-2019), Nissan LEAF (2013-2018, Flex model only) and Smart Fortwo Electric Drive (2009-2014) were available when new with battery lease options. This brought the purchase price down, but meant drivers had to pay a monthly fee for the battery.

Benefits included a performance guarantee and cost-effectiveness for higher-mileage drivers, plus free battery replacement if capacity dipped below the typical 70 percent charge-level guarantee. On the used EV market, prices of these models are still lower than equivalent cars purchased with their batteries.

Some EV battery lease deals required a mileage limit, unless the driver stumped up for an unlimited-mileage option. If you are buying any of these models as a used EV and don’t want to take on a battery lease, check if they are a ‘battery owned’ vehicle.

Battery swapping is another solution to the issue of charging on the move and keeping up with fast-moving tech. The idea is being pioneered by Chinese car brand NIO, which now has over 40 battery swap stations throughout Europe where EV batteries can be removed and replaced in under five minutes. It’s a costly and complex operation, though – and only works with EVs specifically designed for easy battery swapping.

What is the future for electric car batteries?

Solid state EV batteries are set to be the next game-changer. With a chemical reaction very similar to lithium-ion technology, solid state EV batteries replace the liquid-based electrolyte with a solid one. This means solid state electric car batteries are lighter and can be smaller than conventional lithium-ion batteries. These benefits help increase energy density and reduce the battery weight.6

Solid state batteries should last longer and be able to charge faster, significantly increasing both the service life and usability of the vehicle. Safety is improved, too.7

However, they are still technically demanding to manufacture, and much of the technology is still under development. Solid state EV batteries have been mooted for years, but only now are official timelines being given: MG, for example, looks to be among the first brands to take a solid state battery to market, with a production car mooted for 2025.

In the meantime, electric car batteries will come down in price – led by new lithium-iron phosphate technology – while maximum ranges will increase to 500 miles and beyond. Charging speeds will also increase, with increasing numbers of EVs able to use ultra-rapid chargers.

Sources

1 https://www.automotiveworld.com/articles/risky-business-the-hidden-costs-of-ev-battery-raw-materials/

2 https://www.eea.europa.eu/highlights/eea-report-confirms-electric-cars

3 https://www.volkswagen-newsroom.com/en/press-releases/volkswagen-invests-a-further-500-million-in-sustainable-battery-activities-with-northvolt-ab-7246

4 https://www.mercedes-benz.co.uk/passengercars/the-brand/eqxx/stage.module.html

5 https://www.buyacar.co.uk/cars/1523/electric-car-battery-leasing-should-i-lease-or-buy-the-batteries

6 https://www.samsungsdi.com/column/technology/detail/56462.html?listType=gallery

7 https://cosmosmagazine.com/technology/energy/are-solid-state-batteries-safer-than-lithium-ion/

8 https://www.just-auto.com/analysis/how-far-away-are-mass-market-solid-state-ev-batteries/